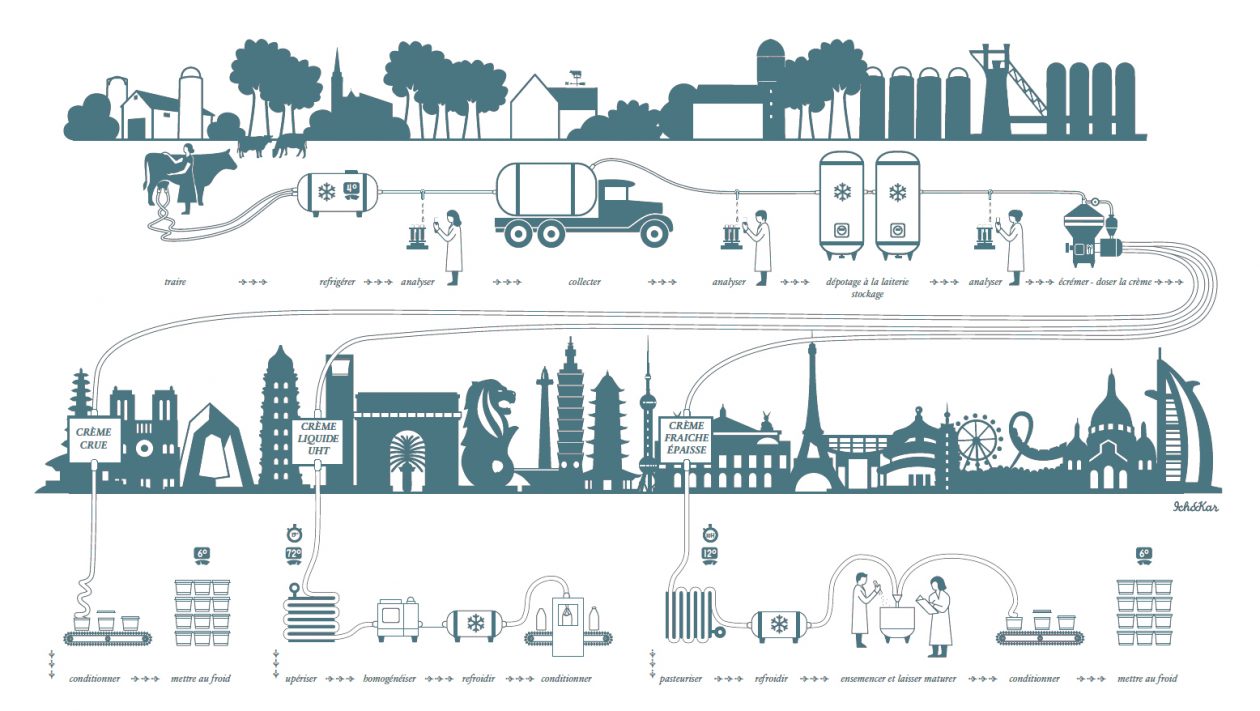

- Samples are taken throughout the manufacturing process.

- Samples are sent to laboratories for analysis based on different criteria.

Benefits :

- For dairies: manufacturing of quality products

- For consumers: a guarantee of food safety and organoleptic quality

繁體中文

繁體中文  简体中文

简体中文  한국어

한국어  Français

Français